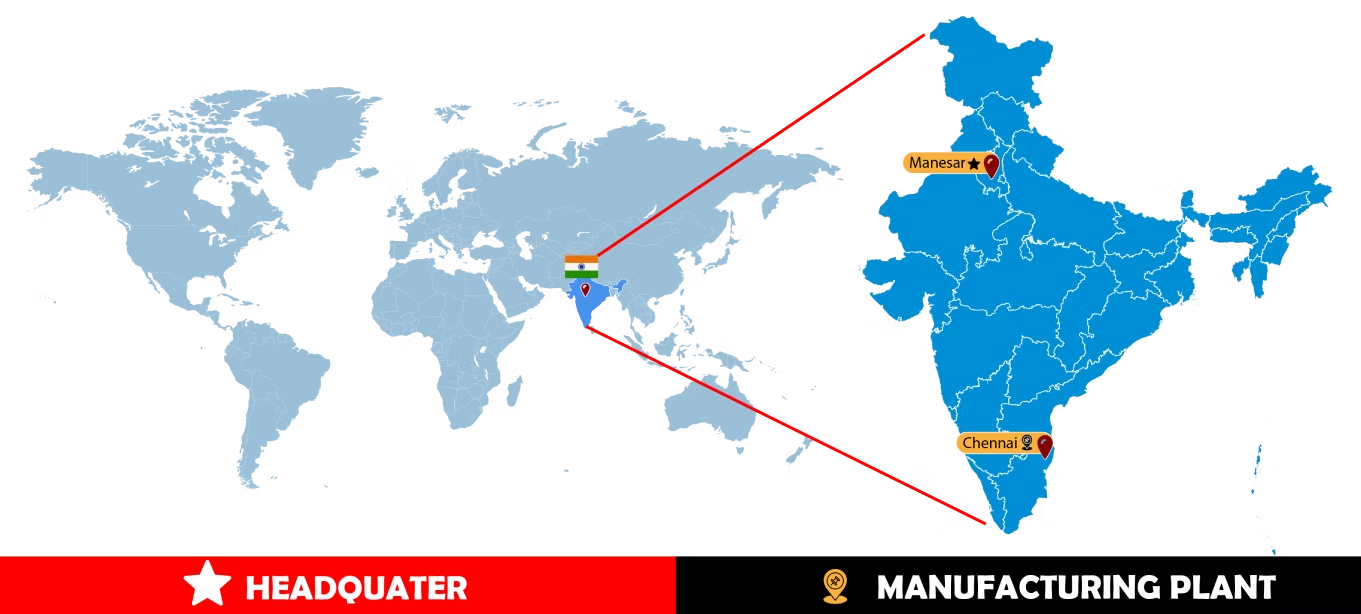

Raja’s Ranee Venture is one of India’s leading plastic solutions providers, offering cutting-edge, high-performance molded components and assemblies to the most trusted automotive brands. Headquartered in India’s industrial hub, our state-of-the-art manufacturing facility is built on strong business values, ethical practices, and a commitment to excellence that spans generations.

Our journey began with a pioneering spirit and continues with a vision to be future-ready—embracing change, innovation, and sustainability to deliver best-in-class products and solutions.