Loading

Loading

With a documented history of over 150 years, our group — formerly known as Raja Toys — has been a pioneer in establishing the toy industry in India.

With sustainability as a prime objective in every decision, we continue to invest in clean and efficient technologies. Our manufacturing facility is equipped with all-electric injection moulding machines (ranging from 100 to 1000 tons), which eliminate the use of oil and significantly reduce power consumption.

Along with blow moulding machines ranging upto 200 liters.

In addition, a 300 KVA solar power plant installed on our rooftop reinforces our commitment to green and renewable energy, driving us toward a more sustainable future.

We specialize in high-volume plastic production with maximum efficiency, ensuring consistent quality and speed.

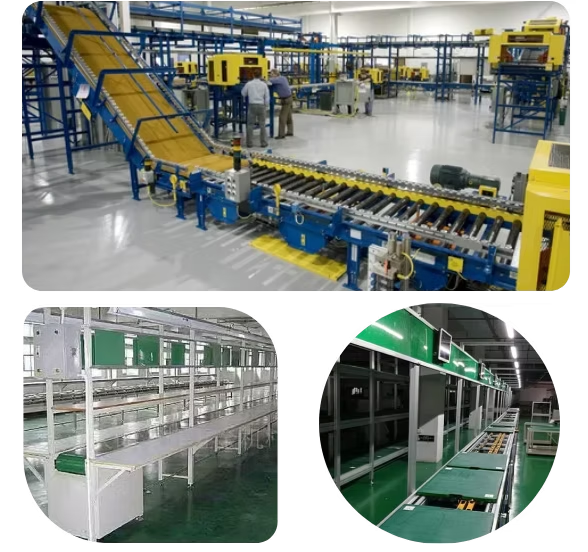

Our advanced EAC Line is designed to streamline the entire production process, delivering precision at every stage.

With a dedicated Raw Material (RM) Storage, we guarantee uninterrupted supply and smooth operations.

A robust BOP Storage system further supports large-scale production and inventory management.

To maintain safety and efficiency, we operate a well-organized EAC Storage facility.

Finally, our in-house testing facility ensures every product meets the highest industry standards before delivery.

Our advanced EAC Line is designed to streamline the entire production process, delivering precision at every stage.

| Particulars | Details |

|---|---|

| Floor Size for EAC | 30000Sqf. |

| No. of Assembly Lines | 4 |

| Length of assembly line | 50Mtrs. Each |

| Manufacturing capacity/day | 600-800 per shift or 1200-1600 per day |

Our cutting-edge CNC plastic machining ensures unmatched precision and consistency in every part. We specialize in producing superior quality components designed to perform in demanding applications. With advanced technology and skilled expertise, we deliver parts that meet exact specifications. From prototypes to high-volume production, our solutions guarantee reliability and durability.

Offering advanced CNC plastic machining services for complex plastic components.

In-house tool fabrication and CNC machining capabilities for custom tooling and dies.

Achieving tight tolerances and consistent quality across multiple production runs.

We work with a broad range of engineering plastics, including high-performance thermoplastics.

| Particulars | Details |

|---|---|

| No. of Multi Meter Panels | 3 |

| HiVolt breakdown Tester | 1 |

| Motor temperature Tester | 1 |

| No. of Multimeter | 2 |

| Tachometer | 2 |

| Anemometer | 2 |

| Decibel Meter | 2 |

| CMM | Installed in 2019 |

With sustainability as a prime objective in every decision, we continue to invest in clean and efficient technologies. Our manufacturing facility is equipped with all-electric injection moulding machines (ranging from 100 to 1000 tons), which eliminate the use of oil and significantly reduce power consumption.

| Electric Range – 180 tons – 950 Tons | |||

|---|---|---|---|

| S # | MACHINE MAKE | MACHINE SIZE (TON) | TOTAL NO. |

| 1 | TOYO (Robotic) |

950 | 1 |

| 2 | 850 | 1 | |

| 3 | 680 | 1 | |

| 4 | 350 | 4 | |

| 5 | 280 | 5 | |

| 6 | 180 | 1 | |

| TOTAL | 13 Nos. | ||

| Hydraulic Range – 110 tons – 910 Tons | |||

|---|---|---|---|

| S # | MACHINE MAKE | MACHINE SIZE (TON) | TOTAL NO. |

| 1 | FERROMATIK MILACORN |

910 | 1 |

| 2 | 550 | 1 | |

| 3 | 450 | 2 | |

| 4 | 350 | 2 | |

| 5 | 250 | 3 | |

| 6 | 150 | 1 | |

| 7 | EURO MACHINERY | 400 | 2 |

| 8 | 230 | 1 | |

| 9 | 180 | 1 | |

| 10 | 160 | 1 | |

| 11 | 125 | 1 | |

| 12 | 110 | 1 | |

| TOTAL | 17 Nos. | ||

We have four latest Blow molding machines fully automatic For use in packaging of 200ml-200ltr. We also have larger Blow molding machines at our other plants.

| Range – 200 ML – 200 LTR | |||

|---|---|---|---|

| S # | MACHINE MAKE | MACHINE SIZE (TON) | TOTAL NO. |

| 1 | RANASONS | 200 | 1 |

| 2 | JAGMOHAN & KEV | 100 | 2 |

| 3 | RANASONS | 50 | 2 |

| 4 | 30 | 2 | |

| 5 | 10 | 1 | |

| 6 | JAGMOHAN | 5 | 2 |

| TOTAL | 13 Nos. | ||

In addition, a 300 KVA solar power plant installed on our rooftop reinforces our commitment to green and renewable energy, driving us toward a more sustainable future.